Taking stock of your supply chain

Mar 23 2022

The Covid-19 pandemic has caused a number of logistical headaches across global supply chains over the last two years. With no end to the uncertainty in sight, perhaps now is a good time to perform a health check of your supply chain.

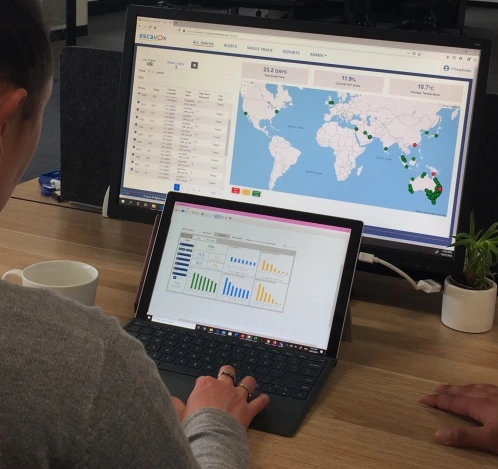

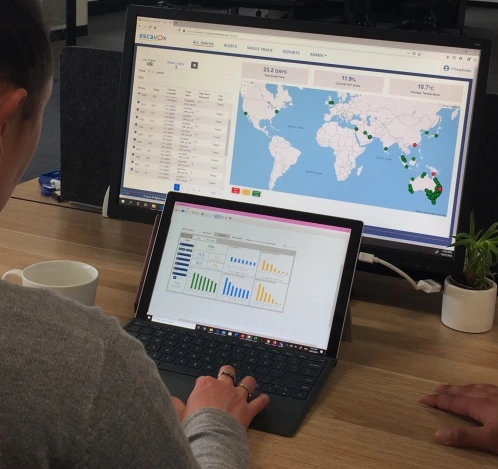

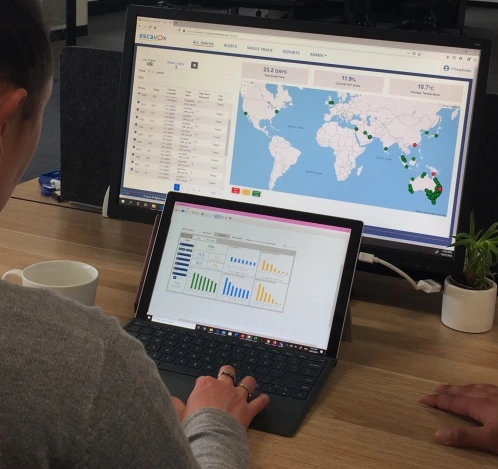

AgTech Finder-listed Escavox is an Australian-owned supply chain intelligence business, providing data insights on the experience of food transported around the globe.

The data Escavox provides is helping food suppliers take greater control of their supply chain operations, particularly critical at a time when Covid-19 is continuing to disrupt global freight networks. AgTech Finder spoke with Escavox chief executive, Luke Wood (pictured below), for his insights.

AgTech Finder: Beginning with the impact the Covid-19 pandemic has had on global supply chains, can you explain why we are seeing shortages and bottlenecks occur around the world?

Luke Wood: Think of a motorway. It is designed to do one thing and do it well – allow traffic to move in one direction, quickly. We remove traffic lights, junctions, any predictable obstacle to enhance the functionality, yet all it takes is the person in front of you to hit their brakes and the gridlock ripples all the way back up the road. People feel it miles from where it first started.

Covid is the guy in front that just hit their brakes and now the gridlock is echoing up the supply chain. We have designed our supply chains to do one thing and do it well; in this case, remove working capital. We do this by accelerating the movement of product, centralising production and reducing order size.

Financially we look great; we reward low numbers for Days Stock on Hand, we incentivise for asset utilisation rates. We seldom rewarded risk management and have limited cultural experience of disrupted supply.

Covid arrives and a simple thing happens: people can’t go to work so production slows down, consumption slows down, and suddenly, we need to change. A ship that was supposed to dock no longer can so the port designed to move containers to create space for the next arrivals no longer can either and we grind to a halt.

And much like a motorway, we cannot get off the road and find a new path; we must sit and wait while we slowly let it unfold.

ATF: With that in mind, are you surprised by how the industry has fared over the last two years?

LW: I am impressed with how the industry has fared. We have faced surging and unpredictable costs, timelines and markets. We have had to learn new skills quickly and adapt; all while facing our own local disruptions at home and in the workplace. It has been a stressful time for all of us in one way or another.

ATF: Shortages of AdBlue, fresh groceries and household items, and even Rapid Antigen Tests, have all been linked back to supply chain issues at one time or another. Do you see these global trends continuing, and how does the industry recover?

LW: Unfortunately, they will continue for a while as we are a long way back in the tail. We recover two ways, initially by learning how to manage disruption. Modern supply chains are complex, known as ‘wicked’ problems. There is no solution, just management. Many people in this space are not used to working with such high levels of disruption and are starting to leverage data and technologies not previously used.

Secondly, we will change our approach to supply chains and put it front and centre of corporate strategy and risk management. It will no longer be considered a back-room function but a priority – the ability to deliver has proven its real value. I expect to see investment in this space in all areas: physical assets, people and technology.

ATF: How important is a well-managed supply chain for both a small business and an entire country?

LW: They are mission critical. If your source of supply is unpredictable or unreliable, you cannot make any commitment to your customers. This applies irrespective of business size or government. With current cost spikes and disruption, a poorly managed chain will be the difference between profit and loss.

ATF: What are the most important factors Australian producers need to consider when reviewing their supply chains?

I’m going to boil it down to five, key questions producers need to be asking. They are:

- What is my objective – cost, service, reliability?

- Where is the weakest link – supply, transport, or access?

- Do I understand my true cost to serve?

- What risks do my suppliers have?

- How important am I to my suppliers?

ATF: What does the future of supply chain management look like to Escavox? Can the industry continue to operate as it did pre-pandemic?

LW: No, the industry cannot continue as before. The public has changed their view and supply chains are at the centre of conversations in every pub and home in the country. If you cannot manage it, predict it, and adapt to disruption you will fall behind.

The future of supply chains is data rich and led by people and technologies that can translate data into outcomes to meet an objective, rapidly. We will see more automation in some areas and an investment in education.

ATF: How does Escavox help its users understand and manage their supply chains?

LW: We are a source of real time and strategic information about how the supply chain and food interact. Fresh food supply chains have a unique constraint – the product is physically changing. How much it changes impacts price, quality and safety. These are all key factors when considering what product to buy and sell.

Escavox captures, measures and presents this impact to operational managers, allowing them to make timely informed decisions. We also collate this information over time to allow long-term strategic decisions to be made.

With the outlook still uncertain in global freight networks, there’s possibly never been a more important time to receive support from the certainty of an independent and objective data trail to provide one source of truth about what’s really happening within supply chains.

Posted in Farmer Advice

You Might Also Like

Jul 23 2025

Low yields from wheat production? Here’s why.

For the past two decades, agronomists and farmers have been trying to solve the problem of low yields using Variable Rate Fertilisation application. However, yield is only half of the equation. In-field…

Read MoreMay 25 2025

Get more from your livestock data with these six agtech solutions

Farmers across Australia are producing more data than ever. But much of it remains frustratingly siloed. Here’s how you can get the most from your data as a livestock producer.

Read MoreMay 20 2025

Purchasing AgTech? Ask yourself these five questions first.

Whether it’s your first time, or you’ve already got plenty of technology in operation – asking the right questions ensures you take the best approach.

Read MoreApr 22 2025

Building farm data trust

At AgTech Finder we ask vendors to provide their data policies so that farmers can make informed choices about agtech and be comfortable about the way their data is being collected and…

Read MoreList your company on AgTech Finder.

AgTech Finder helps Australian Farmers and producers find the product that’s right for them.

Register now to be a part of the community, get access to a national platform and start gaining insights to improve your products.