Spring means harvest time is approaching for many of Australia’s grain cropping regions, and after a number of very dry and disappointing years, growers finally have something to look forward to. While 2020 has served up some difficult challenges in many respects, it also saw a return to better cropping conditions in many parts of the country, with good rains falling at the right time.

Grain is not the only commodity being harvested when a farmer steps into a harvester; there is data being gathered too. This data provides the farmer with feedback on their past agronomic management and helps inform future decisions for managing their cropping program and grain marketing.

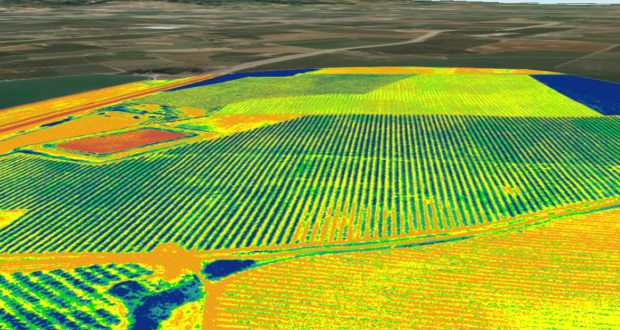

Image: www.farmmanagement.pro

Yield monitoring

The technology that allows harvesters to map yield is not new. It was introduced in the 1990s and initially just tracked total weight, average moisture, and tonnes per hectare. The introduction of GPS tracking allowed growers to gain a better understanding of yield variation across their paddocks and identify underperforming areas.

But identifying low-yielding areas is just the first step. A grower then needs to understand why some parts of the paddock are underperforming before they can take steps to rectify the situation.

There are many reasons why an area might be performing poorly, such as waterlogging, acidity/alkalinity, compaction, plant available water (PAW) or frost damage. While some of this information could be gleaned from conducting soil tests and looking at historical paddock records, the potential of remote sensing also became apparent.

Trimble Connected Farm is an example of software available for yield monitoring. Explore this solution in the AgTech Finder Directory.

Remote sensing

Remote sensing – images from satellites or UAVs – has provided growers with an additional layer of information throughout the cropping season. By recording infrared light waves reflected from the crop, satellites generate a normalised difference vegetation index (NDVI), which can indicate plant stress due to water or nutrient deficiencies, pests and/or disease. It is also useful to allow growers to plan their marketing strategy, as yield is better able to be estimated with the additional information provided.

See remote sensing solutions from Cibolabs in the AgTech Finder Directory.

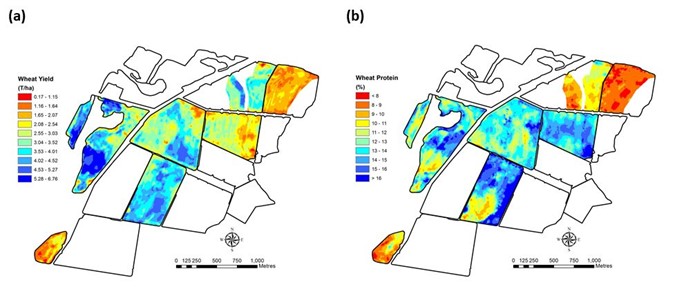

Spatial pattern of wheat grain yield (a) and wheat grain protein content (b) across a farm in northern NSW. Image: Brett Whelan (University of Sydney)

Grain quality monitors sensors

Grain yield is not the only target a grower aims for. In the case of cereals, protein content and protein quality are the main criteria in determining the grain quality, and hence the price per tonne they will be paid. In the case of oilseeds, oil content is critical.

Harvesters can now be fitted with grain quality sensors that use near infrared spectroscopy (NIRS). Previously, grain samples had to be stationary for quality to be measured, but the technology now exists to measure quality from a continuous grain flow, hence it can be measured as it is harvested.

Explore Hone’s handheld spectrometer in the AgTech Finder Directory.

Nitrogen management and variable rate application

Protein and oil content are heavily influenced by the amount of nitrogen available to the growing plant, so ensuring the correct rates of nitrogen are applied goes a long way towards ensuring grain quality and optimising efficiencies.

By combining the various technologies outlined above to build a comprehensive picture of a paddock’s health and history, growers and their advisors can prescribe a nitrogen application program that will optimise their nitrogen use.

The ability to map a paddock and apply nutrients and ameliorants according to where they are needed has been a game changer in terms of the economics of cropping. Amelioration of soil constraints such as acidity and sodicity can be expensive, so avoiding the waste of over-application or the lost yield potential of under-application makes good economic sense.

Nitrogen is somewhat different in that the relationship between NDVI and yield and is usually site and year specific (being substantially influenced by growing season rainfall). This means that the demand estimated from other paddocks or seasons could be incorrect in the current season. However, in a promising GRDC-funded project ‘Future Farm’, the CSIRO is examining the potential of sensors and machine learning to determine the optimum amount of nitrogen needed.

Explore Laconik’s nitrogen calculation technology in the AgTech Finder Directory.

Promoting adoption

While the use of technologies such as GPS autosteer in the Australian grains industry is widespread, there is considerable potential for the uptake of more recent mapping and management practices such as yield, protein and NDVI mapping, and variable rate application. Support in the form of extension and skilled advisors makes a difference, as evidenced by the more rapid adoption of precision agriculture tools and practices in areas where agronomist support and availability are greatest.

Explore Agtrix Farming Crop Inventory and Data Recording tools for mapping and recording crop attributes in the AgTech Finder Directory.

Agtech Finder Directory

Search the AgTech Finder Directory for specific agtech solutions for your farm.